Waste Reimagined

Advancing technology to enable a world without waste

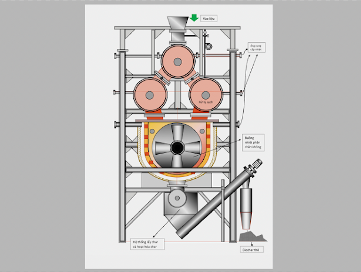

What we doWe specialize in manufacturing proprietary Radiant Heat Equipment and Magnetic Vacuum Thermal BioChemical Technologies

HOW WE DO ITBringing all types of Waste into the Fourth Industrial Revolution

Our Smart Waste System processes all types of mixed-contaminated waste, eliminating bacteria, odors, and viruses through Radiant Heat and Magnetic Vacuum Thermal Biochemistry processing. This technology converts general waste into clean, non-contaminated, renewable energy sources like hydrogen and e-fuels. It employs sophisticated electronics and intelligent controls to streamline the entire process, from fuel selection to gas and electricity generation for community and industrial use.

-

-

/

SMARTWASTE Playlist

Waste to Clean Energy

15 Tons per Hour MSW SMARTWASTE Artificial Intelligence, Inc Circular Economy Process

THE FACTS: How much food is wasted in America?

SMARTWASTE Zero Waste Solution/ Clean Energy Production

SMARTWASTE Artificial Intelligence Zero Waste / Zero Landfill to Clean Energy

Zero Waste Pyrolysis process

Waste to Clean Energy

15 Tons per Hour MSW SMARTWASTE Artificial Intelligence, Inc Circular Economy Process

THE FACTS: How much food is wasted in America?

SMARTWASTE Zero Waste Solution/ Clean Energy Production

SMARTWASTE Artificial Intelligence Zero Waste / Zero Landfill to Clean Energy

Zero Waste Pyrolysis process

EQUIPMENT & PROCESSES Technology synthesized by decades of experience in the waste industry, renewable energy and environmental protection with both our American and Vietnamese group of scientists.

Our Scientists have invented technology to treat these types of waste in the field of automatic, intelligent biochemistry - physics and mechanics. Use DME gas fuel or DME liquid fuel to generate electricity. With 120 Ton/day we can generate 10MW of electricity.

Hydrogen Production

Specifically, the technology refers to the conversion of solid waste and biomass into clean fuel, from clean fuel of size to syngas and steam reforming and revolving the gas in a vacuum pyrolysis environment. Non-magnetic to regenerate and grow to capture the highest hydrogen content (over 28%) In solid waste synthesis gas of all types and biomass, the gas components include CO, CO2, H2, CH4, C2H6, C2H4, C8H8. These components, in addition to the Hydrogen collected by the scientists mentioned above, are also passed through the steam reaction. reverse rotation of the carbon cycle (active convection) to capture as much hydrogen as possible from synthetic gas and fuse with hydrogen produced on site (electrolysis from pH water) to convert into E-fuel energy ( e-fuel) and other energy products such as carbon, tar, oil.

DME Production

Electronic fuel (e-fuel) is also known as synthetic fuel, such as e-kerosene, DME, E-Methane or E-Methanol. E-fuels are produced using carbon dioxide, or captured filtered carbon monoxide, reacting with hydrogen obtained from water electrolysis through sustainable "clean" electricity sources such as Trash power, wind power , solar power and nuclear power. Based on principles. Magnetic vacuum thermal biochemical technology two scientists invented and designed a process for producing pure hydrogen gas and electronic fuel, activated carbon, and amorphous carbon powder from all kinds of solid waste (personal household waste). , industrial waste, medical waste, toxic waste, poultry and livestock waste, human waste, agricultural, forestry and seafood wastes.

MARKETS & MATERIALSCapturing Recyclable Resources at Scale.

Get in touch to learn more about how our technology can revolutionize your business.

-

![]()

PLASTICS

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more.

-

![]()

PAPER

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more.

-

![]()

METALS

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more.

-

![]()

CONSTRUCTION

Description goes here

-

![]()

ELECTRONICS

Description goes here

-

![]()

ORGANICS

Description goes here